Starlogic (Jiangsu) Technology Co., Ltd is an intelligent internal logistics system solution and service supplier with a core of “Smart manufacturing+ Smart logistics”, and is committed to tailor-made solutions for customers in different industries from planning & consultation, project design, data simulation, equipment development, software development, installation and commissioning, personnel training, after-sales service, remote operation and maintenance in one integrated digital factory system solution.

The lane-type stacker is the main equipment for handling and accessing goods in the intelligent warehouse. lt is a special crane developed with the use of the intelligent warehouse. The main purpose of the lane stacker is to shuttle back and forth in the lane of the high-rise racks, store the goods at the entrance of the lane into the cargo positions, or take out the goods from cargo positions and transport them to the lane exit.

The system consists of a parent shuttle and a child shuttle. The parent shuttle mainly moves horizontally on the track to receive goods taken out by the child shuttle. The child shuttle is used to store and retrieve goods, moving vertically on the track. The parent-child shuttle can move through the lanes in a multi-level warehouse, positioning and retrieving/storing goods on multiple deep, which improves storage density and transportation efficiency.

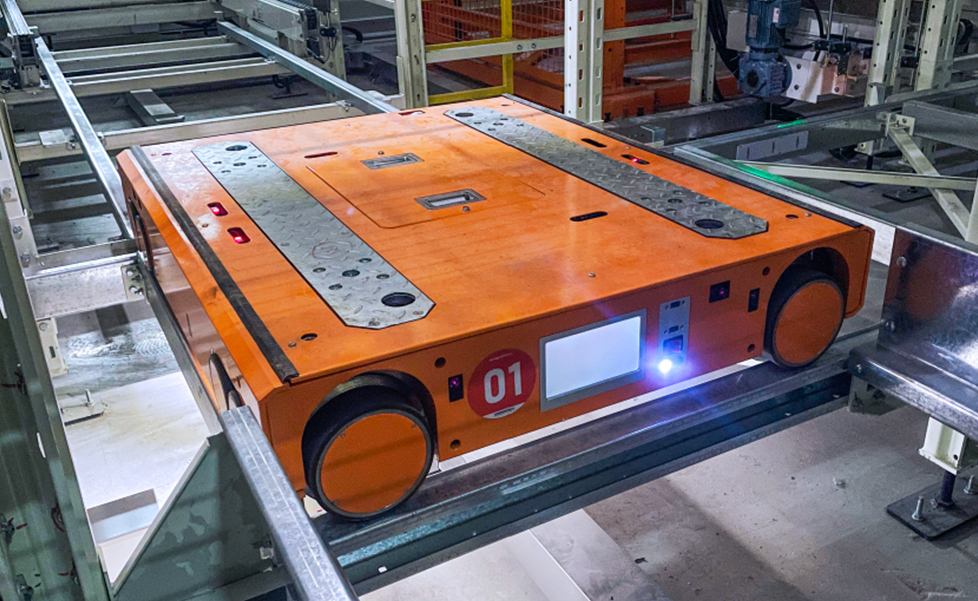

The four-way shuttle is an upgraded version based on the traditional one. It can move horizontally and vertically at the same level without turning. By connecting with WMS and other systems, one shuttle can complete tasks including retrieving, transporting, and placing, and can move on multiple levels with a lift, which is flexible and intelligent in scheduling.

AGV refers to a series of related equipment and devices that move, store and control materials by coordination. Because material handling only increases the cost and does not increase product use value, the rationality of the material handling system directly affects the production efficiency and economic benefits.

Loop/straight rail guided vehicle is an important system in AS/RS, which can be applied to various types of high-density storage warehouses. The scheduling system uses intelligent algorithms to automatically plan the paths for RGV. The RGV rail can be designed to any length, which can improve the storage capacity and operation efficiency with higher safety.

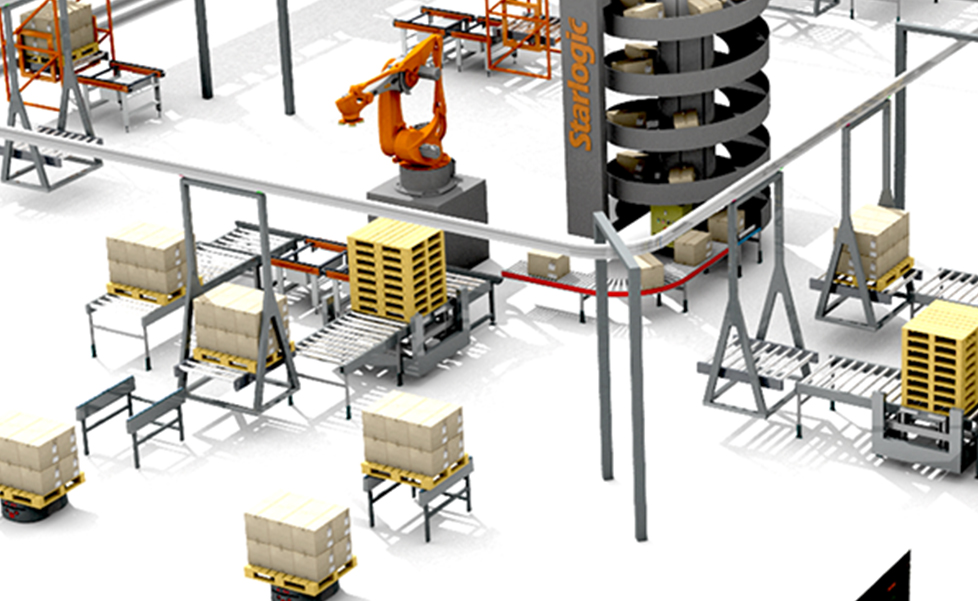

In the input and output system of the automatic warehouse, the pallet automatic conveying system has been commonly used for pallet conveying to complete the automatic pallet input and output, The different input & output capacity needs different equipment selection and layout which will directly affect the conveying efficiency and project cost.

Case conveying system is different from the pallet conveying system, and the conveyed goods are usually standard-size containers, such as cartons, bins, etc.; the system can quickly and accurately transport the items to the designated position through belt conveyor, multi-wedge roller conveyor, picker, and continuous lift etc. It is widely used in e-commerce, express delivery, pharmaceuticals, clothing and other industries, with high transportation efficiency and low item loss.

The Air EMS conveying system is a conveying system in which the drive motor obtains power through the controller and trolley line or non-contact power supply technology to drive the traveling wheels to travel on the aluminum alloy track in the air to drive the trolley.

An all-in-one solution developed for increasing market demands in terms of packaging flexibility and handling efficiency for a wide variety of containers and packages, suitable for packaging bottles, cans, cases, wrappers, trays and interlayers equipment and systems for palletizing/depalletizing and handling.

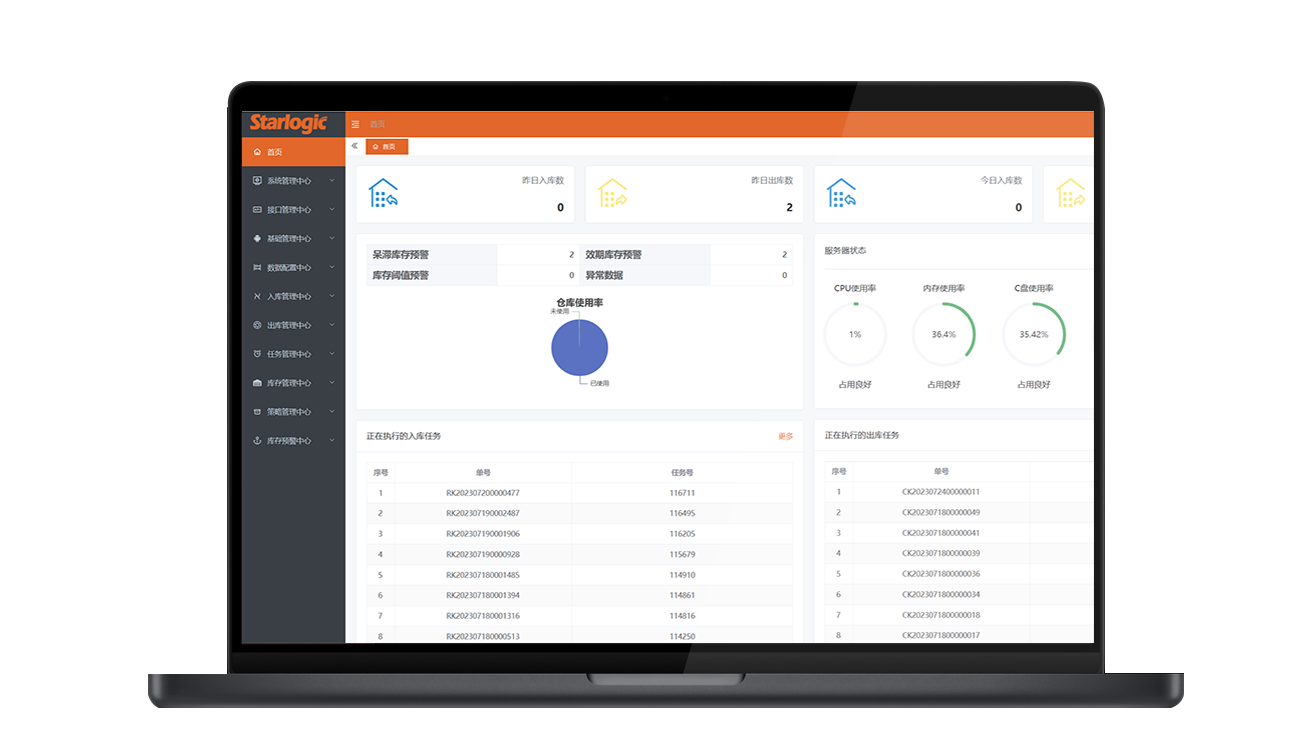

The development of warehousing system is inseparable from the two key factors of logistics equipment and logistics software. Usually, automated warehouse logistics system software consists of two parts: Warehouse Management System (WMS) and Warehouse Control System (WCS).

The automatic storage system can be divided into three systems. The WMS acts as the brain of the facility, responsible for the processing of warehousing business logic. The logistics equipment like stacker and AGV system etc. acts as the command executor. The WCS system is responsible for coordinating and scheduling various logistics equipment, so that the logistics equipment can execute the business process of the warehousing system. The whole process is completely executed according to the preset process of the program.

Build an efficient and high-quality logistics warehousing system, optimize the overall operation of the supply chain, improve the overall distribution efficiency, and realize the management, control and data visualization of logistics warehousing in the whole factory.

Relying on the self-developed WMS/WCS/TMS logistics management information system, Starlogic effectively combines logistics equipment and software system, uses fast and accurate information processing functions,and integrates the information of the whole process of production and storage.

It is a (web-based) operational software under the "supply chain" grouping. It can improve logistics management capabilities through a variety of methods and other related operations; including managing shipping units, specifying intra-enterprise, domestic and foreign shipment schedules, managing transport models, benchmarks and costs, maintaining transport data, generating bills of lading, optimizing transport schedules, selecting carriers and modes of service, soliciting bids and tenders, auditing and paying freight bills, processing claims for damage to shipments, arranging for labor and space, managing documentation (particularly when international transport is involved), and managing third-party logistics. Managing documentation (especially when shipping internationally) and managing third-party logistics.

SCADA system is a computer-based DCS and electric power automatic monitoring system, which can be applied to electric, metallurgy, petroleum, chemical, gas, railway and other fields of data acquisition, monitoring, and process control.

In the warehouse management system, the SCADA system can monitor and control the operating equipment on site to achieve data acquisition, equipment control, measurement, parameter adjustment and all kinds of signal alarm and other functions, which is known as the "four remote" function.

MES can provide management modules including manufacturing data, planning and scheduling, production scheduling, inventory, quality, human resource, work center/equipment, tooling, procurement, cost, project dashboard, production process control, underlying data integration analysis, upper-level data integration and decomposition etc., create a solid, reliable comprehensive and feasible manufacturing collaborative management platform for enterprises.

Business Intelligence mainly refers to the clear and effective transmission and communication employing graphical means. To effectively transfer ideological concepts, aesthetic forms, and functions need to be gathered to achieve deep insight into rather sparse and complex data sets by intuitively conveying key aspects and features.

Business Intelligence is closely related to information graphics, information visualization, scientific visualization, and statistical graphics. Based on the data and their intrinsic patterns and relationships, computer-generated images are used to gain deep understanding and knowledge, and the vast bandwidth of human sensory systems is used to manipulate and interpret complex processes, involving datasets of different disciplines and the simulation of large abstract data sets from diverse sources.